EXPANSION ELECTRONIC IS THE FIRST EUROPEAN MANUFACTURER THAT HAS OBTAINED THE UNI EN ISO 16890 CERTIFICATION ON ACTIVE ELECTROSTATIC FILTERS.

The introduction of the new global standard UNI EN ISO 16890, which classifies the air filters on the basis of their ability to retain the dispersed airborne particulate matter (PM10, PM2,5 and PM1), is generating a general revolution in the air filtration sector. It replaces the previous and obsolete EN 779:2012 standard (F7, F8, F9), anti-dust air filters for general ventilation.

![]() EN ISO 16890 CERTIFICATION BROCHURE WITH COMPARATIVE TABLES AND FORMULAS

EN ISO 16890 CERTIFICATION BROCHURE WITH COMPARATIVE TABLES AND FORMULAS

CHARACTERISTICS OF EN ISO 16890

• It replaces an existing standard from more than 20 years.

• The efficiency refers to the particle size of fine powders.

• The classification of a filtration element in a ePMx group is based on the minimum value of efficiency.

• New procedure for the electrostatic charge on the entire filter.

• Two different aerosols for the test: DEHS and KCL.

ADVANTAGES OF EN ISO 16890

• The filters will be more suitable for the real conditions of the desired application.

• Easier to correlate with international organizations such as WHO (World Health Organization) thanks to the same nomenclature.

• Possibility to calculate in an engineering way a filtration system.

• Improvement of the Indoor Air Quality.

• The norm will be valid worldwide.

The main difference between the previous EN 779 standard and the new EN ISO 16890, for the users, lays in the classification system of the HVAC filters efficiency.

In order to be classified as PM1, PM2,5 or all other PM size classes, a filter must prove a minimum efficiency of 50% compared to the class concerned. So, with this norm a filter can have up to four efficiency classes if it reaches minimum 50% of efficiency in the PM class (n).

In the end, for coarse filters, the new standard will include the filters that capture less than 50% of particles in the PM10 range, which will be called Coarse ISO and will show the performances of PM10 (for example PM Coarse 45%).

The medical-scientific community also recognizes the problem about micro-particulate and is paying special attention to PM 1, which is considered the most dangerous fraction of PM for human health. This new standard will therefore lead to an improvement in indoor air quality for the benefit of the health and well-being of people and production processes.

Thanks to their properties, the active electrostatic filters of Expansion Electronic offer very low pressure drops, constant during normal operating life. When the maximum degree of dirt is reached, the electrostatic filter can be maintained by washing with a special detergent that regenerates it and guarantees its normal functionality again.

The active electrostatic filter is a high precision filter composed of noble materials and is not intended for “disposable”. The return on initial investments is guaranteed in a few months thanks to:

• lower energy consumption that still guarantees a high Indoor Air Quality;

• lower maintenance costs;

• no filter replacement costs.

The FE SYSTEM filter range generates saving on energy costs of 30%.

The reliability and performance of Expansion Electronic filters, in fact, ensure low running costs throughout the entire life cycle of the plant.

------------------------------

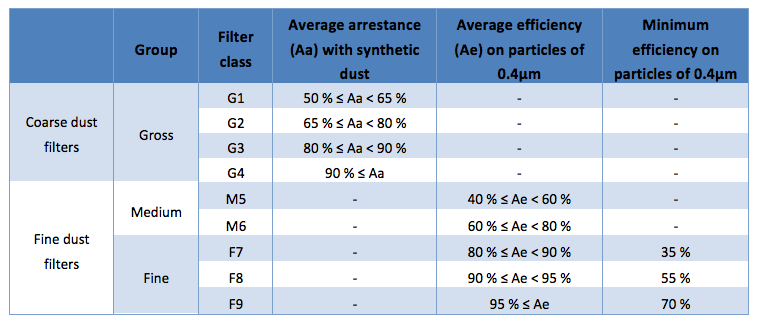

REPLACED NORM

The European standard EN 779:2012 entitled “Particulate air filters for general ventilation” constitutes the relevant legislation for test and classification of filters used in general ventilation and way of test for measurement of performance of filter. This European standard refers to the filters for air purification which starting efficiency is less than 98% evaluate on polluting particles of 0.4 µm (micron).

The methodology described in the standard is based on a laboratory test procedure, with the aim of achieving reproducible and comparable results.

Filters are tested with a test volume flow between 0.24 m3/s (850 m³/h) and 1,5 m³/s (5400m³/h): since a filter’s operational behaviour depends on the volume flow in operation, the filter classes and all other test results from the test performed in accordance with EN 779:2012 always relate only to the test volume flow specified in each case. The principal results of the test are:

- Gravimetric arrestance efficiency;

- Efficiency on 0.4 µm particles;

- Pressure drops;

- Dust holding capacity.

The most significant change connected to this European standard – that was adopted in Italy in June of 2012 – is about the introduction of minimum efficiency for Fine filters (F7, F8 and F9) and the renaming of Fine filter classes F5 and F6 as “Medium”, that is M5 and M6.

The introduction of these minimum efficiencies represents a milestone in the filter industry as it raises the quality standards, improving the care of human health.

The European standard EN 1822:2012 is the reference standard on air filters with high and very high efficiency filters and with ultra-low penetration (EPA, HEPA and ULPA): this norm establishes a procedure for the determination of efficiency of filters using a method for the quantitative estimate of pollutant particles remaining after treatment with liquid aerosol. In this way it’s possible to obtain the classification of filters in a normalized way, facilitating the European commercial exchanges.

The methodology described in the standard EN 1822 permits to:

- Asses the efficiency of filters, counting particles hold by the filter and size for which the efficiency of the filter is minimal. This size is known as Most Penetrating Particle Size (MPPS);

- Check for the leaks of filter, local and total.

Compared to the previous standard published in 1998, efficiency classes H10, H11 and H12 have been renamed as E10, E11 and E12.

Following the enactment of this norm absolute filters are classified as follows:

- EPA 10 – EPA 12 : Efficiency Particulate Air Filters

- HEPA 13 – HEPA 14 : High Efficiency Particulate Air Filters

- ULPA 15 – ULPA 17 : Ultra Low Penetration Air Filters

The technical national standard UNI 11254:2007 titled “Active electrostatic air filters for general ventilation – Definition on filtration efficiency” refers to the air filters intended for general ventilation, functioning through one or more electrostatic fields actively applied by means of a generator.

The content of this norm concerns:

- Classification of filter following the evaluation of average efficiency on particles of 0,4 µm in diameter;

- Complete description of test circuit, test method and procedures for qualification.