With the constant increase in atmospheric pollution, especially in the most industrialised countries, the demand for air filtration is growing sharply. In the context of sustainable development, the need to minimise the power consumption of plants has become of fundamental importance and is being widely researched. The new range of active electrostatic filters with integrated electronics, the FE SYSTEM series, has been designed and developed for this reason. Electrostatic filter FE SYSTEM is an alternative to traditional pocket filter and was designed to simplify the use of electrostatic filters in AHUs and Rooftops. Its use in ventilation systems, particularly in the air-conditioning sector, does not require changes in the construction and dimensional characteristics of the plant.

![]() Technical Sheet / Scheda Tecnica

Technical Sheet / Scheda Tecnica

MECHANICAL FILTER

The mechanical filters are constituted by “little mattress” of mineral fibers, obtain by plants or artificially, through which passed the air. Classified according to their greater or smaller ability to hold particles, the more efficient are defined HEPA (High Efficiency Particulates Air Filter), able of blocking into their tangle mites faeces, pollens, bacteria and any higher particles higher on diameters than their minimum filter length, which on average is from 0.3 to 0.9 microns (the size of a pollen can go from 5 to 250 microns, while that of a virus can vary between 10 nm and 700 nm).

Their performance is directly proportional to the energy consumption and the bill’s costs increase as it increases the presence of pollutants settle over time. On their surfaces we can see a gradual biological proliferation, which is the development of micro-organisms in risk of diffusion inside the environment. Finally, this type of filters involves frequent replacement and disposal costs (in fact there are toxic dangerous wastes, which have to be disposed as hazardous waste). In conclusion, the new mechanical’s filters generation (classes G, E and F) have very good performance during the initial stage of filtration, and then decrease considerably as the filter reaches the maximum concentration of particulate. Therefore they need to be replaced with new filters that initially ensure a good efficiency filtration.

MECHANICAL FILTER WITH ELECTROSTATIC CHARGE

In the electrostatic filtering systems technology there is an electrostatic effect when a polluting particle (dust, smoke, fibers, etc ...) has, on its surface an electric charges (positive and/or negative) that makes it adhere to another surface (filter’s fiber, walls, curtains, TV and laptop screens, etc..) with equal but opposite charge. If the particle mass is sufficiently small, the electric charge presents on its surface makes it adhere to another opposite electric charge, present on the surface of the mattress filter.

When this phenomenon is enhanced artificially, electrostatically charging the fibers of a filter you will obtained a “passive electrostatic filter”, which in order to work well must be made with very high electrical resistivity fibers, as for example the rectangular plastic fibers. Its negative aspect is that just the deposit of polluting particles on the filter fibers makes it immediately decrease the ability of pollution’s abatement.

Moreover, if the environment is particularly damp, the water contained in the air condenses on the surface of the fibers and eliminates them in a very short time each electric charge, transforming the product into a simple mechanical sieve filter. To overcome this problem the so-called ‘buffer’ filtering systems were created, in which the filtering means are submerged in an electric field which maintains the attraction power and the pollutants retention. The negative side is in the operation, starting from the fact that it depends on a filter mattress (the so-called buffer) that, even if electrostatically charged, presents the same disadvantages of the mechanical filters.

ELECTROSTATIC FILTER WITH ACTIVE PLATES

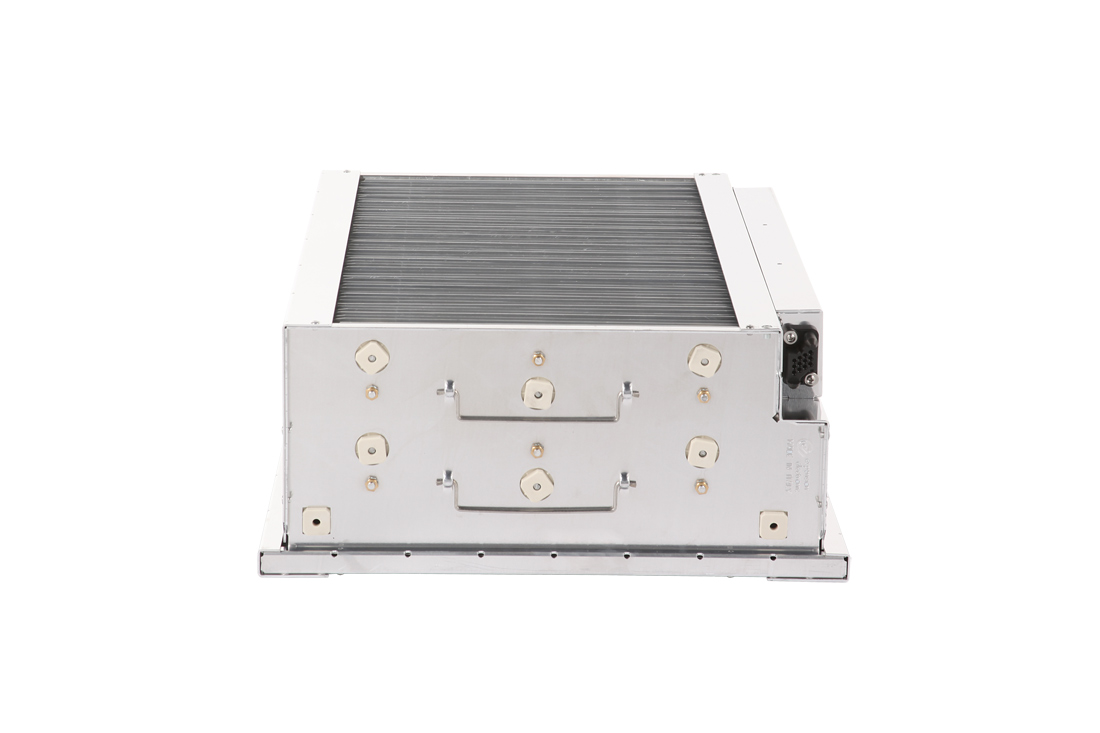

The Expansion Electronic electrostatic filter (electronic filter) is made of aluminium active plates electrostatically charged.

It consists of a purification treatment system that allows the separation of the polluting substances, which can be either in the solid state (dust) and gaseous (oil vapours), from the incoming air flow. The system, through a generated potential difference between the emission electrodes and those of collection, allows the separation of the pollutants from the gas, which flows through the electrodes: in this way the air suspend particles - whatever their size - are electrically charged as a consequence of the generation of an electric field thanks to the emission electrodes. This field generates the particles’ ionization, which, going through the collection field, allows the collision between ions and pollutants. To these substances it is cede, part of the ions’ electric charge, causing the precipitation of the pollutants which are captured and detained by the capture plates. At the end there is the result of a completely purified air from any type of pollutants and, above all, from any polluting dimension.

The FE SYSTEM electrostatic precipitator is equipped with a specific power supply system and electrical adjustment which allows the enhancement of electrostatic charges both on polluting particles and on the collecting surfaces. In practice, the voltage (volt) and the resulting current (mA) ionize the particles and create on the filter surfaces (opposing and subjected to appropriate electrical voltages) a sufficiently intense electric field to capture them, just as if they were attracted by a magnet.

They have the advantage of being very effective in retaining particles, fibers, biological substances even those with a very small diameter (<1 microns) and do not lose filtration capacity over time (as always regenerated) even when the pollutant is accumulated on the filter. The power consumption is very low (about 4.7 w per 1000 m3 of air). The efficiency remains constant throughout all the operation cycle while the duration of the cells is equal to the life of the machine. The state of dirt of the filters is signaled by a sensor that allows to schedule the periodic maintenance, easily executable by the user through the simple washing in water with mild detergent for aluminium.

ENERGETIC EFFICIENCY

Energy management, in the last years, has become a debate’s subject and argument of great interest. In ventilation systems, the air handling process, through the treatment unit, requires a significant waste of energy.

The total amount of the latter, depends on the pressure drop which are directly proportional to the efficiency class of the filters (and therefore the obstruction level) and the level of desired quality inside the unit.

Any “mechanical” air filter, which efficiency depends mainly from mechanical interference phenomena among the particles in transit and the filtering fibrous matrix, undergoes a progressive increase of the load losses, due to the accumulation of deposits compared transverse to the air flow. For example, a filter in the medium to high-efficiency paper, F7-F8 class according to EN 779, can be characterized by the initial pressure drop of 100-150 Pa, which can increase up to 450 Pa at the end of operating life. Now with the new certification EN ISO 16890, the filter replacement it's expected when it reaches 300 Pa (SEE MORE).

The active electrostatic filters, instead, “rub off” the particles in suspension by the air flow and they precipitate on the collectors’ plates, which are arranged along the crossing direction. Thanks to this property, the electrostatic filters offer very low load losses, almost constant during the normal operating life, which ends when the thickness of the deposit begins to disturb the electric field, instead of preventing the passage of air, as is the case in “mechanical” filters. Expansion-Electronic undertakes the use of renewable and recyclable materials till 95%, preserving the environment thanks to products with a longer life cycles. This rise the question of why you do not normally use electrostatic filters in the air handling units.

IMPORTANT GERMICIDE EFFECT

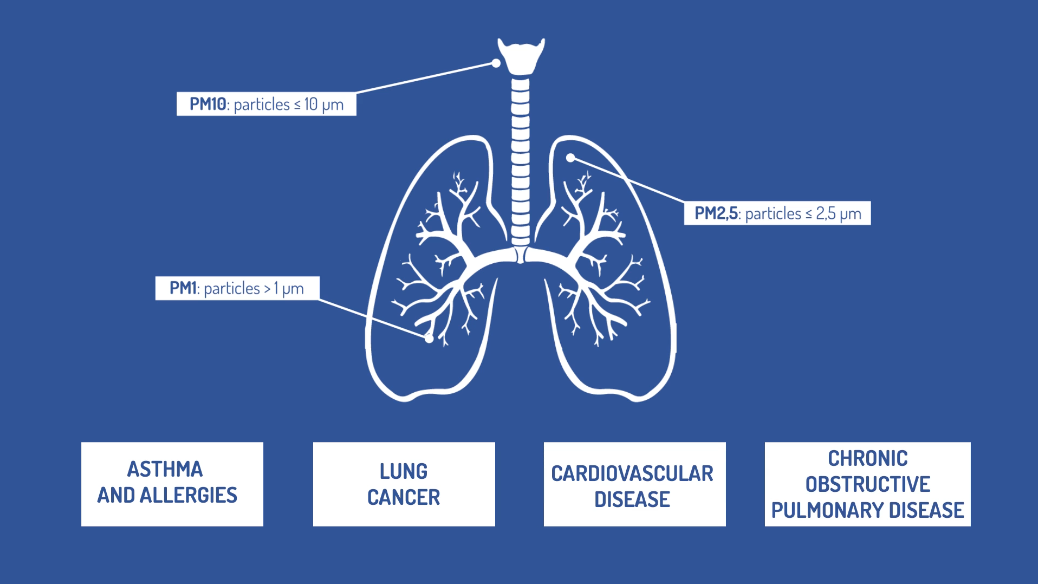

The electrostatic filter has a high germicide power, features that normal mechanical filters do not possess. It is important to focus the attention on the fact that electrostatic filter originates an inactivation of contaminants, unlike the mechanical filtration which does not guarantee it and create in the long run a collection of live contaminants which proliferate and form germs colonies, exposing the environment and the maintenance man operator at a high risk of infection. As you can see in the image below, contaminants, according to their size, they can enter inside our body and wear out certain organs. With electrostatic filters this problem is eliminated as pollen, dust mites, fungus and other contaminants, being captured and inactivated, they cannot enter inside the body and therefore there is an improvement in the individual’s health quality.

The Hygiene Institute of Berlin, which has been operating since a long time on the research, ventilation, environmental technology, medicine and hygiene fields, has certified that our electrostatic filters are able to remove from the air the aero-bacteria dispersed, yeasts and molds with a level of efficiency that goes from 98,53% to 99,96%.

CERTIFICATED EFFICIENCY

Expansion Electronic has developed and lodged several patents and received a certain number of certifications that has enabled us to obtain great success and a large number of international awards. We want to recognize our commitment and value through the certifications and compliance of our products to provide at our customers with absolute quality and efficiency for all to guarantee a complete confidence.

The UNI 11254 norm ranked the active electrostatic filters in four filtration degrees (A,B,C,D). The efficiency considered in this norm is the average efficiency of EM on DEHS granulometry PARTICLE SIZE OF 0.4 μm. An effective comparison with the mechanical filter is not possible, because the efficiency classes of the latter consider:

a) the average filtration efficiencies during the filter’s useful life which are not constant, but increase with the filter’s powder saturation of particles of 0.4 μm (old class F, EN 779).

b) the minimum filtration efficiency for particulates’ size of 0.3 μm (class E, EN 1822).

Nevertheless, the FE electronic filters can be compared with the pocket one (ISO 16890 or E class) according to their performance against the particles’ dimensions. FE electrostatic filter offers, in terms of performance, a growing efficiency of filtration with the decrease of the air flow speed passage. At a speed of 4 m/s an FE electrostatic precipitator will be comparable to a mechanical filter class F 8, while at 1,5 m/s its filtration efficiency will make it comparable to a filter E 11 class.

Therefore, in a variable air-flow system, with an active electrostatic filter the minimum efficiency class will be that obtained at the maximum flow and will growing when the flow decrease. This peculiarity does not exist for mechanical filters that maintain the same class of efficiency at different operating course, although the degree of efficiency is minimum in the new filter.

RETROFIT FOR THE COMFORT AND ENERGETIC PERFORMANCE IMPROVEMENT

The retrofit action aims to improve the current condition, both in terms of energy performance and comfort, of the existing conditioning or ventilation plants with the consequence to have a new qualification of the building.

Retrofit operations, especially in the civil sector, predict the electrostatic filter’s application that ensure very high energy efficiency thanks to their technology construction, the increased filtration efficiency and the reduction of management cost. Usually the FE SYSTEM electrostatic precipitators are installed in AHUs or Rooftops.

Finally, thanks to the material with which were built (aluminium), the filters can be easily regenerate through a simple washing process and its life cycle is about 15/20 years.

Plants characteristics with Electrostatic precipitators (electrostatic filters):

• high efficiency, on the top of E class filtration according to EN 1822 (E10 - E11) till to 2 m/s of speed velocity on the electronic filter;

• low costant pressure drop, compared to the pocket filters currently in use;

• maximum performance linearity (efficiency, pressure drop) during the operative life;

• maximum extension of the operative life (high load capacity in terms of weight of retained pollutants).

These are the basic features, to which is added an extremely important plus: an efficient antifungal and antibacterial action, in order to avoid the proliferation of bacteria colonies and molds in certain favourable conditions of temperature and humidity, often encountered in typical treatment plants air. For these reasons, and in order to reduce environmental impact, Expansion Electronic has implemented a retrofit’s action that allows you to replace the normal mechanical filters with those of new electrostatic generation one.

The advantages are mainly two:

- The lower energy consumption, “energy saving” given by the lower pressure drop and then the re-sizing of existing ventilation fan systems. Thanks to this action is guaranteed a good reduction in CO2 emissions.

- A considerable reduction of the amount of non-recyclable material.

RETURN ON INVESTMENT

The active electrostatic filter is an high-precision filter, composed by noble materials and it is not designated to a “disposable” use. The higher initial cost will be amortized over time (around 2 years) due to:

• Lower energy consumption with an elevate Indoor Air Quality.

• Lower maintenance costs;

• No cost for the replacement of the filter.

We calculated the return of investment taking into account the two different filtration technologies, electrostatic filter and mechanical.

We used the international formula developed by Eurovent for the electric power (Kw/h). During the evaluation of the cost is easy to understand that there is a significant investment for using electrostatic filters than the mechanics one, but this investment is offset by the large energy savings resulting in lower cost of electricity and with consequently less maintenance costs/replacement of filters. Mechanical filters must be replaced at least three times per year and this means a big economic expenditure.

The range of FE SYSTEM electronic filters generates a saving on energy costs equal to 30%. Reliability and performance of Expansion Electronic filters ensure low operating costs throughout the entire life of the plant. We can guarantee a quick return on investment estimated at about 2 years.

APPLICATION FIELDS

the new range of electronic air filters FE SYSTEM, could be installed in:

- air handling units (electrostatic filter for AHU);

- rooftop (electrostatic filter for Rooftop);

- ventilation ducts.